Subiaco plant may trial conversion of sludge to oil for electricity

2/5/96

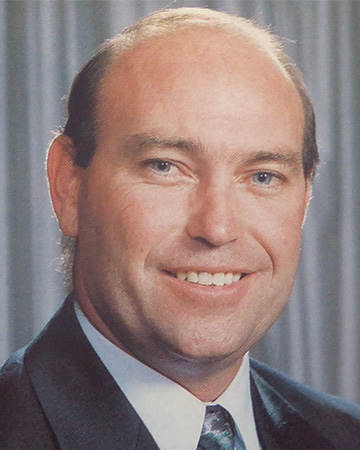

The Water Corporation's Subiaco wastewater treatment plant may become the first facility in the world to convert sludge to oil to generate electricity on-site, Water Resources Minister Roger Nicholls announced yesterday.

Mr Nicholls said the corporation had selected the oil from sludge process - known as Enersludge - to solve an environmentally sensitive issue relating to odours at the plant as well as providing sustainable sludge treatment to 2040.

He said Perth-based Environmental Solutions International Ltd (ESI) would be the sole tenderer and if the tender was satisfactory the company would build a plant and implement its Enersludge process by the end of next year (December 1997) at an estimated cost of $19 million.

If the tender was not acceptable, modern sealed egg-shaped digesters would be constructed.

"As well as providing a modern solution to sludge treatment and disposal, the most obvious initial benefit would be that the process eliminates all odours from the waste digestion process and therefore substantially reduces total odours from the plant," Mr Nicholls said.

"Residents in the Subiaco and Shenton Park areas will be pleased to see progress on this long standing odour problem".

Mr Nicholls said the present sludge treatment process was carried out partly in open sludge digester tanks and the resultant odours were carried for long distances.

The Enersludge process would occur in a specially built facility containing sealed units and the air flow in and out of the facility would be tightly controlled.

The existing digesters would be gradually de-commissioned.

"The Enersludge process uses a patented, low temperature conversion system to convert organic sludges into hydrocarbons in much the same way that Mother Nature produces crude oil," Mr Nicholls said.

"However, while it takes millions of years to convert organic matter to oil, this process only requires 30 minutes to convert organic constituents in sludge to a diesel-grade oil, a low grade coal type char and gas and reaction water.

"The char and gas would then be recycled to provide the thermal energy for the process while the oil would be used to produce electricity."

"In fact, instead of purchasing electricity from Western Power, the corporation would make its own electricity at the plant and make savings of about $700,000 a year.

"Based on that alone, the corporation could expect to recoup its entire $19 million investment within the life-span of the process, which is expected to be operational until at least the year 2040," Mr Nicholls said.

He said the possible use of the Enersludge process demonstrated the Water Corporation's commitment to innovative and environmentally sound wastewater technology.

Mr Nicholls said the Enersludge concept evolved in Germany, but over the last decade ESI had transformed the concept into a practical engineering solution.

He said benefits of the Enersludge process included:

energy efficiency with low capital costs and low operation and maintenance costs;

100 per cent recycling of sludge;

production of reusable by-products available for use on site;

100 per cent destruction of human pathogens and viruses;

destruction of organochlorine compounds;

immobilisation of heavy metals;

control of odours;

low greenhouse gas emissions with minimum air pollution; and -

elimination of the potential for groundwater contamination.

Media contact: Hugh Ryan 221 5468